Sept. 30, 2022 Edition

“If you’re looking to modify a fertility program to achieve higher yield output, just realize that it takes the soil 3-4 years to fully adapt to those nutrient changes.” – David Sass, Pioneer Field Agronomist in the Pacific Northwest

To help

emphasize this point, we could iterate that crop yields three to four years in

the future will be influenced by our management practices being employed

today. If you have conducted some tissue

tests and/or expanded soil testing in some higher production fields to push

productivity, understand that it takes time for significant fertilizer

applications to be absorbed by the soil.

The patience we must display in agriculture can be frustrating at times,

but usually the long-term rewards for enhanced management are well worth the wait.

Weather

Well, the weather to date has been tolerable with many above

average days lately and most operations finding a steady rhythm to this season’s

harvest. We’ve had the usual array of

weather events, and just when we were getting a little too dry for comfort,

most areas have received some needed rainfall over the past several weeks. The below NDAWN rainfall map from mid-August

to the end of September reveals a strong pattern to the north and east in our

region as receiving more rainfall.

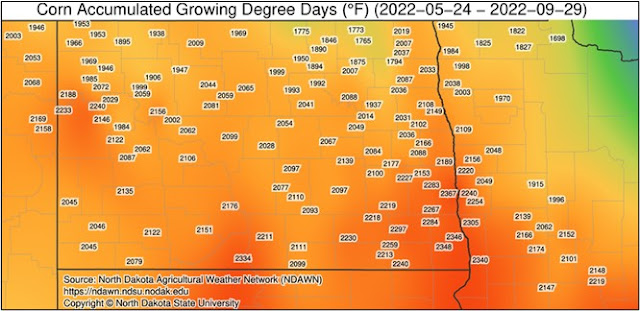

Our corn GDDs were above average from June 1st to the end of September (see map), and it was much needed with a cool and wet spring which prevented completion of planting/sowing until early to mid-June. With an average corn planting date for our region of May 24th, our full GDD accumulation for the season places most areas with at least 2000 GDDs and traditionally cooler geographies to the north and outside the Red River valley in the 1750-1900 range which is within a couple days of average. Overall, at the end of September, most operations feel fortunate with the season’s weather to date and are optimistic in both crop yields and finishing the needed field activities for the year.

Crop

Progress

Most of the corn is in the final stages of development with

a starch line of at least ¾ths of the way down the kernel. Many fields have reached a natural black-layer

and I’ve heard reports of 27-28% grain moisture. If you did happen to receive a killing frost on

the corn and the starch line was at the half-way point, the research data

indicates anywhere from a 5-10% yield impact.

This decrease in yield would come from lighter kernel weight and thus

taking more kernels to fill a 56 lb bushel basket.

With the late season moisture in most areas, abundant

sunshine during grain fill, and minimal acres impacted by a killing frost, I am

seeing good late season plant health in the corn and soybeans which will lead

to good harvest standability. Kernel

size in soybeans and test weight in corn should be above average as well.

For the soybeans, most fields have already reached full

maturity and are dropping leaves quickly.

Soybean harvest is just getting underway with initial yield reports above

average significantly – 10 bu/ac or more.

It could be a record soybean crop for production in our region if those

trends hold.

The weblinks provided below will provide some additional

information on managing a frost damaged soybean and/or corn.

https://www.pioneer.com/us/agronomy/managing_delayed_or_frostdamaged_soybeans.html

https://www.pioneer.com/us/agronomy/Managing_for_DelayedCorn_Crop.html

Genetically

Engineered for SCN?

When you have a pest that is as significant as the soybean

cyst nematode (SCN), it’ll take all the tools in the toolbox and more to assist

in keeping populations manageable. Back

in June, the EPA granted registration of a genetically engineered Bt soybean

from BASF that will target SCN.

Currently, “the trait is only registered for use as breeding material”

and is forecasted to become commercially available in 5-6 years. The Bt trait is providing “moderate

suppression” of SCN and will not be promoted as “control”. To further enhance SCN effectiveness, BASF

plans on combining the Bt trait with resistant genetics like PI88788, Peking,

or future cyst resistant genes to improve upon effectiveness against the

pest.

The Bt protein (Cry14Ab-1) attacks the gut of the cyst

nematodes in a similar fashion that corn Bt traits like YieldGuard and

Herculex1 control European Corn Borer.

Cyst resistance to the Bt gene is forecasted to be minimal due to low

mobility of the nematodes in the soil and the combination of resistant genes in

conjunction with the Bt genetically engineered trait.

Corteva and BASF have agreements in place to bring the next

generation of herbicide tolerant soybeans (Enlist-3 with PPO herbicide tolerance)

and the SCN Bt trait together for germplasm in the 2030 decade.

https://www.dtnpf.com/agriculture/web/ag/crops/article/2020/08/19/basf-develop-bt-soybean-targeting

PowerCore

Enlist Corn - Next Generation of Technology

Corteva has received all domestic and international

regulatory approvals for the next generation of Bt and herbicide tolerant corn

for our region. “PowerCore Enlist” will

contain three distinct above ground Bt proteins to control European Corn Borer,

Fall Armyworm, and other potential insects as well as herbicide tolerances of

glyphosate, glufosinate, 2,4-D choline, and FOPs. Common FOP chemistry includes the Group 1

herbicides like Assure II® (quizalofop), Fusilade® (fluazifop), Discover®

(clodinafop), etc. The FOP chemistries

will primarily provide an option for volunteer corn control in corn-on-corn

rotations (presuming a non PowerCore hybrid was planted the prior year). Secondarily, in fields where glyphosate

resistant grass weeds are of concern, FOP genetic tolerance will provide

another technology option.

Volunteer corn from PowerCore hybrids in a succeeding

soybean (or other broadleaf) crop can be controlled by Group 1 DIM herbicides

like clethodim (Select Max®), sethoxydim (Poast®), etc.

PowerCore Enlist hybrids will be tolerant to 2,4-D

choline at 1 lb a.i./ac rate up to 30” corn height. This would equate to a full quart or 32 oz/ac

of LV4 2,4-D and be equivalent to Enlist soybeans at 2 pts/ac of Enlist One

herbicide. Yes, 2,4-D has been labelled

on corn for many decades, but PowerCore Enlist corn will bring a much larger

window of application, and significantly higher use rates without the added

risk of fused brace roots that cause lodging or increased susceptibility to

green brittle-snap. With the new choline

formulation, we’ll continue to see near zero volatility/drift onto neighboring

susceptible crops (as we’ve witnessed with Enlist One and Enlist Duo applications

in E-3 soybeans). Overall, just another

tool in the box for our quickly evolving weed spectrum.

PowerCore Enlist corn will begin to slowly appear in the

70-75-80 and 85 RM zones within the next couple years from Pioneer and Corteva.

https://www.pioneer.com/us/news-and-events/news/media-release/powercore-enlist-corn.html

Corteva

Purchases Symborg

Corteva Agri-sciences has made the move and reached

agreement to purchase Symborg, a microbiological technologies business. Corteva and Symborg have a history of working

together to bring Utrisha-N to the marketplace as a nitrogen efficiency

optimizer in corn, soybeans, and wheat over the past couple growing seasons. This transaction by Corteva is another step

in the proper direction to continue to bring leading technological solutions to

crop producers across the world.

Combine

Harvest Solutions

Mr. John Aubin has been running his

business of “Combine Harvesting Solutions” since 2010 and relishes in

opportunities to engage with farms while assisting with dialing-in the combine

for maximizing efficiency in the field.

John has knowledge of all brands and models of combines while diagnosing

and solving thrashing issues in the field.

Below are a couple of

key harvesting tips from Mr. Aubin:

- Closely monitor the consistency of the crop flow across

the header and into the feeder housing.

The more consistent this flow is, the better the crop will thrash

internally as the grain will naturally begin to separate as it rubs

against itself (material on material thrashing). As the need for machine thrashing decreases

due to this rubbing, the more efficient (greater speed/less grain loss) the

combine will become

- Insure the cross-auger in the header (if so equipped)

is square from left to right in its height above the platform as well as

in its depth from the back of the header – obviously a square header auger

is essential to create consistent crop flow

- For corn, measure the diameter of a thrashed cob

(millimeters) and then set the combine rotor clearance to that exact

measurement as a starting point. In

this example (pic), the measurement is about 23 mm

- It’s a good practice to double check and potentially

re-calibrate electronic measurement displays in the cab regarding combine

settings. It is not uncommon for an

electronic display to be off by a significant percentage and therefore could

be the actual cause of excess grain loss despite the operator thinking the

particular setting is spot-on or should/cannot be adjusted any further

- Also for corn, make sure the deck plates are slightly wider apart at the rear (top) of the deck plates versus the bottom (front). This will ensure the rollers will more efficiently pull the stalk through and therefore more effectively allow the residue to flow properly with less stalk material having to move through the combine.

If you have a machine (or two or more) that isn’t gathering or thrashing grain as effectively as you’d like, or is having issues with excess grain loss or a dirty grain tank sample, I’d recommend giving Mr. Aubin a call. He is excellent at walking through concerns over the phone or in the field and assisting growers in solving problems. He is an independent consultant so he will charge for his time, but these charges are minimal when considering the value of today’s commodity output and the number of acres a machine will harvest in a crop. John Aubin’s contact info is within his website:

http://www.combineharvestingsolutions.com/about-us/

Comments

Post a Comment